Data: Thu 08 Feb 2007 - 09:18:09 MET

Message-ID: <000b01c74b59$ab176c40$041d9c95@kh002007>

Content-Type: multipart/related; type="multipart/alternative"; boundary="----=_NextPart_000_0007_01C74B62.0CA29BD0"

Near net shape: CastCon - A New Manufacturing Approach to Produce High Performance Components

IMP HOME

STAFF

METALLIC PROCESSING

CastCon - A New Manufacturing Approach

to Produce High Performance Components

CastCon is a new manufacturing approach which combines casting, forging, P/M, bonding and coating in one process to produce high performance components. CastCon begins with a sand mold formed with a pattern and made from a selected sand and binder mixture. A powdered material is fed into the cavity of the sand mold either dry or wet. The powdered material is then heated and isostatically pressed with a high pressure source. The sand mold acts as a pressure transmitting medium, uniformly consolidating the powdered material within the mold.

CastCon produced parts

The major advantages of the CastCon process include:

a.. excellent shape forming capability inherited from the vast usage of sand molding techniques in the metal casting industry;

b.. good mechanical properties equivalent to forged parts due to zero porosity and fine microstructure;

c.. great flexibility of producing a wide variety of metallic, intermetallic, ceramic and composite components facilitated by using various powdered materials and their mixtures;

d.. capability of producing macro composites by bonding different powders, or a powder to a solid, or a solid to a solid;

e.. an unique powder coating method for improving abrasive and corrosion resistances;

f.. a production process suitable for both single piece and high volume production.

The CastCon process is rapidly approaching commercialization. Opportunities currently exist to implement this advanced manufacturing process in a production application. Product flexibility, superior properties, and a reduced total cost make the CastCon process enticing to members of the rapidly advancing manufacturing community. Interested parties should contact us for more details.

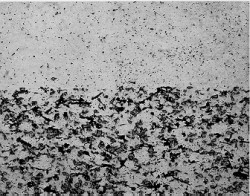

Al/Al+20%SiC+5%graphite bonding

(An optical micrograph, about 100x)

More Information about CastCon

a.. CastCon Prototyping Service

b.. Properties of CastCon Produced Materials

a.. 316 Stainless Steel

b.. Co-Cr-Mo Alloy

c.. Co-6 Alloy

d.. D7 Tool Steel

--------------------------------------------------------------------------

...Back to the Metallic Processing Page